MINIHYDRO POWER PROJECT

Mini Hydro power project, Polis is the major and tremendous achievements of IRDWSI, during the year 19990-2000. according to the power demand analysis to Putsil villagers, the proposed mini hydro power project is now in action. it is therefore reasonable to expect a high surface run off during the rainy season resulting in they still load in stream water.

The project successfully completed because of the people's contribution and dedication of their work with a strong commitment unity among them. From the beginning of the progarmme the whole village people. around 200, including women and children worked hard till the completion of the project.

To meet the financial barrier of the maintenance of the project. Villagers arranged a fund by collecting a minimum of Rs.20/- from each house per month.

Mini Hydro Power Project - Follow Up

The follow up activities of the Mini Hydro Power Project of Putsil village is a regular programme. At the initial phase the Hydro project functioned smoothly without any defects. Problems cropped up only after one year. Gradually, from then onwards various kinds of minor problems followed one after the other. The main problems were

a) Cable Problem

The 1300 metres aluminium armour cable used as transmission line from the power house to the village often get short circuited during rainy days due to faulty displacement at the time of laying the cable underground. As the cable was under the earth ft was very difficult to locate the exact spot as the team lack the regulatory mechanisms needed to evaluate such event. At present, it is administered by cutting the cable wire at four different locations and ensure regular continuity test. Under such circumstances, once the short circuited sites were identified the two ends of the cable were easily attached by using M-seal cable joint . As a result of the above loopholes, current transmission was interrupted in the entire area consecutively for a week. A decentralized policy was adopted for maintenance and operational work. Often technicians from outside were hired to repair the damages. Technical assistance has been provided by the core staff. They constituted a village level committee members to foresee smooth functioning of the project and to tackle any matter arising out of it.

|

|

(b) Voltage Drops After Lighting Load

In the evening when there was heavy load of current, the voltage tend to drop drastically from 415v to 340v. After an enquiry it came to light that the sudden fall of power was attributed to the use of excessive fluorescent lamp. In order to bridge this lacuna decision was made to affix additional power with a capacity of 10 KVAR at the distributing end to check the voltage stumble. A 10 KVAR capacity of L&T has been purchased for this purpose.

|

|

(c) Low Turbine Speed

The peltron turbine consisted of two nozzles. When the two nozzles were in operation the speed of the turbine tends to slow down. At normal speed, when one nozzle was operated, the speed of the turbine is 980 RPM. But when both the nozzles were operated at the same time the recorded speed was 720 - 750 RPM. But it was supposed to maintain the same RPM. In order to match the discrepancy, a study was conducted on the flow of water in the pen stock with the help of an expertise Mr. Sunith. After completing the study it was decided along with the consultant of the project M/s Aroville Energy Products, to minimize the size of one of the nozzle. The top nozzle (N2) size was reduced to Y2 of that of the lower nozzle. Finally, after repairing and induction of smaller size nozzle, the problem was solved and power restored.

(d) Defective Electronics Load Controller

The generator is connected with 3 Electronics Load Controller in three phases which controls automatically the frequency of the generator out put. It also indicates whether the turbine is low, high or normal. Due to lightning hit 2 of the 3 ELC were not functioning. Therefore, the load of the generator needs to be cautiously maintained by the responsible technicians. At present adjustment was made. The project is not in possession of the spare parts required. Spare parts have been already requested and notified to the supplier of ELC, who in turn, have to import the spares. Rectification work will be immediately set out once the goods are delivered. Apart from this, maintenance work on other parts were carried out. The technicians clean the generator carbon brush & slip ring, removal of silt deposits in the check dam and ensure steady water flow inside the channel. Electricity consumer fund was initiated in the village. So far, the total amount of funds collected under the consumer funds is Rs. 21,000. Recently, an extra shaft was purchased from the market to replace the existing one, as it was bent and corroded the same was replaced.

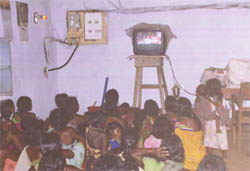

Mill House - Putsil

With the access of electric power, a mill house was set up to cater to the needs of the people. The aims was to cater to its neighbouring villages. Machines for grinding, rice hulling, flour mill and oil extraction were housed at the Mill House. Construction of the mill house was completed in the month of May. But due to lack of trained personnel among the villagers the machines could not be operated. Besides the additional revenue accumulated from servicing the mill, the work load of women are on the decrease, as traditionally, in a Adivasi society daily chores like pounding-of rice and pulses are considered to be the manual responsibilities of the women.

Computer accounting format was developed to maintain accounts. Village committee was set up to manage the mill. They selected 3 landless persons ( 2 male & I female women) to run the mill. Certain amount was fixed for every grain processed in the mill. The amount collected as revenue from the services of the mill, 50% of the total amount will be paid to those in charge of the mill. Another 25% will be deposited to the electricity consumer fund and the remaining balance (25%) will be earmarked for mill house maintenance. At present, rice huller operates efficiently . For flour mill & oil explorer, one trainer is yet to be recruited for a month to train the village personnel who are in charge of the whole operations.

Solar Home System - Panasput

The core team follow-up the solar home system which was given to the villagers as an experiment to study the feasibility of its long term loan basis. Out of the 1 0 solar lanterns 6 of them were not functioning. However, the disorder was due to faulty handling of the equipment by the person-in-charge rather than other defects of the technology. As a consequence, the repayment of loan could not be recuperated as envisaged upon.

After a meeting with the village community it was decided that the equipment will be handed over to some other person who is competent enough to take care. The aim of the experiment is to develop the renewable energy option, and if successful, integrate into income generation programmes as part of it.

Besides this follow up programme, core staff attended meetings on health, water and sanitation conducted by DST, New Delhi. A project proposal on sanitation & safe drinking water facilities for Barakotni village was prepared and submitted to the Government.